2026 How to Choose the Best Stainless Steel Wire Mesh?

When selecting the best stainless steel wire mesh, several factors come into play. The material's quality is crucial. Stainless steel wire mesh offers strength and durability. It is essential for various applications, from construction to food processing. However, not all stainless steel wire mesh is created equal.

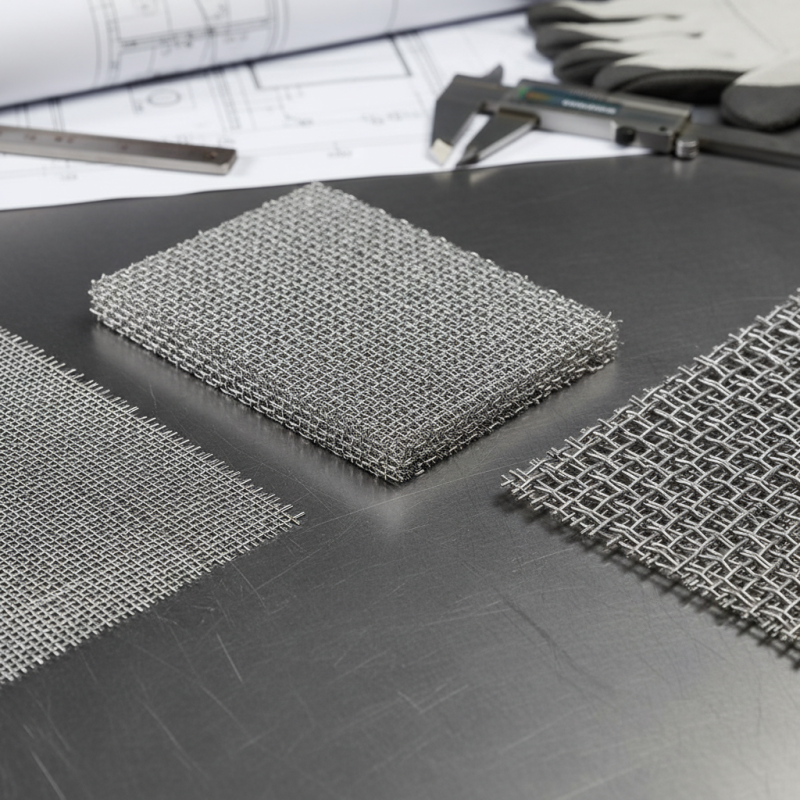

Consider the mesh's weave and gauge. Different weaves offer unique benefits. A tighter weave provides better filtration, while larger meshes allow for more airflow. Additionally, gauge influences strength. A thicker gauge means a sturdier product. Yet, one must balance strength with flexibility.

Also, think about corrosion resistance. Ideally, the stainless steel should withstand harsh environments. The right choice depends on intended use. It can be a challenge to find the perfect match for specific needs. Reflecting on these aspects can lead to better decisions. Ultimately, the right stainless steel wire mesh can significantly impact performance.

What Is Stainless Steel Wire Mesh and Its Common Applications?

Stainless steel wire mesh is a versatile and durable material widely used in various industries. Its strength and resistance to corrosion make it ideal for applications ranging from filtration to construction. In food processing, for instance, it ensures safety by filtering contaminants while allowing for efficient processing. The wire mesh's ability to withstand extreme temperatures adds to its functionality, especially in industrial settings.

Another common application is in architectural design. Architects use stainless steel wire mesh for facades, creating modern and eye-catching structures. Its aesthetic appeal draws attention, but installation can be tricky. Not all designs accommodate the mesh’s weight and flexibility. It requires careful calculation to ensure stability and visual harmony.

Despite its benefits, stainless steel wire mesh is not without challenges. Sizing the mesh correctly is crucial; using the wrong gauge can compromise its effectiveness. Cost is another consideration. While it may seem expensive upfront, its longevity often justifies the investment. Reflecting on these factors can help in choosing the appropriate type for specific needs.

Key Factors to Consider When Selecting Stainless Steel Wire Mesh

Choosing the right stainless steel wire mesh hinges on a few key factors. Each application requires specific properties to ensure optimal performance. Assessing the mesh's size is crucial. The opening size greatly affects airflow and filtration. Smaller openings can trap finer particles but may restrict airflow.

Another consideration is the wire diameter. Thicker wires offer durability, while thinner wires provide flexibility. It’s essential to strike a balance based on your needs. The mesh’s grade also matters. Different grades provide varying levels of corrosion resistance. You might find it challenging to navigate between options without knowing your environment.

Surface finish can alter performance as well. A smooth surface may simplify cleaning but could also attract more contaminants. Pay attention to these details. It's easy to overlook such factors in the selection process. Take your time to reflect on each aspect before making a final decision.

Understanding Different Grades of Stainless Steel for Wire Mesh

When choosing stainless steel wire mesh, one must consider different grades of stainless steel. Each grade offers unique properties, suited for various applications. For example, 304 grade is widely used due to its balance of strength and corrosion resistance. It's ideal for indoor use and environments with moderate humidity.

On the other hand, 316 grade stainless steel provides superior corrosion resistance, particularly against chlorides. This makes it better suited for marine environments. However, this comes at a higher cost. If you focus only on price, you may overlook the long-term benefits of quality materials.

Understanding these differences is crucial. A poor choice can lead to quicker degradation of your mesh, resulting in costly replacements. Sometimes, people overlook maintenance needs based on the grade. It’s vital to reflect on your specific environmental requirements. Are you using the mesh in a high-humidity area? Consider the implications of corrosion over time.

Mesh Size and Wire Diameter: Their Impact on Mesh Performance

When selecting stainless steel wire mesh, mesh size and wire diameter are crucial factors. The mesh size refers to the opening dimensions. A smaller mesh size provides finer filtration. This is ideal for applications like sieving, where precision matters. Yet, fine mesh can also clog easily. It's essential to balance fineness with flow rates.

Wire diameter plays a significant role too. Thicker wires increase strength and durability. However, they can reduce mesh's openness. This limits airflow and fluid movement. A heavier wire can resist deformation. But if it's too heavy, the mesh becomes cumbersome for certain tasks. Experimenting with both factors helps find the perfect fit for your needs.

Choosing the right combination requires reflection on your specific application. Consider the environment's demands. A solution that works in one scenario may fail in another. Sometimes, a trial-and-error approach reveals unexpected insights. Adjustments can lead to improved performance. Embrace the learning process. The right choice often comes from understanding both materials and their practical implications.

2026 How to Choose the Best Stainless Steel Wire Mesh? - Mesh Size and Wire Diameter: Their Impact on Mesh Performance

| Mesh Size (inches) | Wire Diameter (mm) | Open Area (%) | Applications | Strength (MPa) |

|---|---|---|---|---|

| 0.5 | 0.45 | 23 | Filtration | 520 |

| 1.0 | 0.60 | 38 | Screening | 480 |

| 2.0 | 0.80 | 50 | Architectural | 460 |

| 3.0 | 0.85 | 65 | Guardrails | 440 |

| 4.0 | 1.00 | 72 | Safety Guards | 420 |

Comparative Analysis of Cost vs. Quality in Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, cost and quality often collide. A recent industry report stated that around 70% of buyers prioritize price over quality. This approach can lead to compromises in durability and performance. A lower-quality mesh tends to corrode faster, especially in harsh environments. In contrast, investing in higher-quality materials can extend the lifespan of the mesh significantly, sometimes by 50% or more.

Analyses show that high-quality stainless steel wire mesh might cost 20-30% more upfront. However, the long-term savings often outweigh this initial investment. Many businesses report a reduction in maintenance costs with premium materials. For example, facilities that opted for quality mesh saw a 40% decrease in replacement frequency. Yet, some vendors still push the narrative of lower costs without emphasizing potential risks.

Balancing cost and quality isn't easy. Many buyers find themselves caught in a cycle of purchasing cheaper options, only to face issues later. It's crucial to assess specific needs. The right choice should consider the mesh's application and environment. Sometimes, a slightly higher upfront cost can lead to peace of mind and improved efficiency down the road. Knowing these factors is vital for making an informed decision.