How to Choose the Best High Speed Wire for Your Projects?

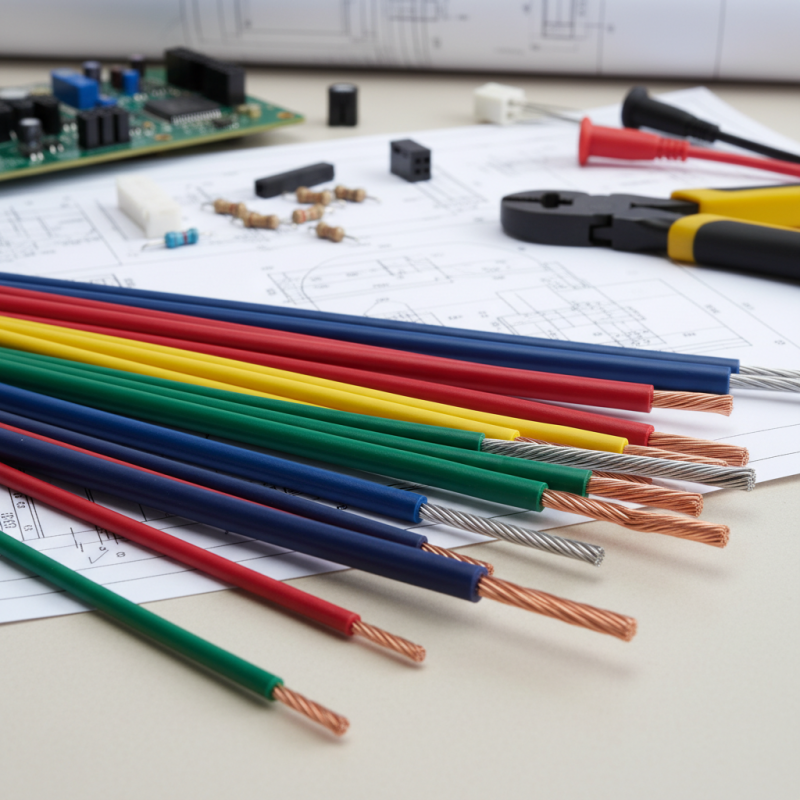

Selecting the right high-speed wire can significantly influence the success of your projects. Many factors come into play when choosing this essential component. Different materials, gauge sizes, and insulation types can lead to various performance outcomes.

High-speed wire is critical for applications that require quick data transmission. Using the wrong wire can result in signal loss or slower connectivity. For instance, copper wire is well-known for its excellent conductivity. However, some may overlook it due to cost.

It's easy to follow common trends while selecting high-speed wire. Yet, this might not always be the best strategy. Every project is unique, and a deep understanding of requirements is vital. Reflecting on past choices can help avoid common pitfalls. In the end, making an informed decision ensures efficiency and reliability in your projects.

Choosing the Right Wire Gauge for High-Speed Applications

Choosing the right wire gauge is crucial for high-speed applications. The wrong gauge can lead to

data loss, overheating, and inefficiency.

According to industry reports, using too thick a wire may reduce flexibility. Conversely, too thin a wire could restrict current flow.

Proper selection is essential for optimal performance.

When working on high-speed projects, consider the wire's ampacity. For example, a

20 AWG wire typically handles around 3.5 amps, while a 12 AWG can handle up to 20 amps.

However, the gauge may vary based on the application. Always calculate the load to avoid unexpected failures.

Tips: Maintain a balance between performance and flexibility. Sometimes, the best solution

is not the thickest wire. Conduct a thorough wave analysis to align wire choice with your project's speed requirements.

Remember, proper insulation also plays a significant role. Inadequate insulation could lead to

signal degradation. Always inspect wire shorts, as these can compromise the entire system.

Understanding Different Types of High-Speed Wires and Their Uses

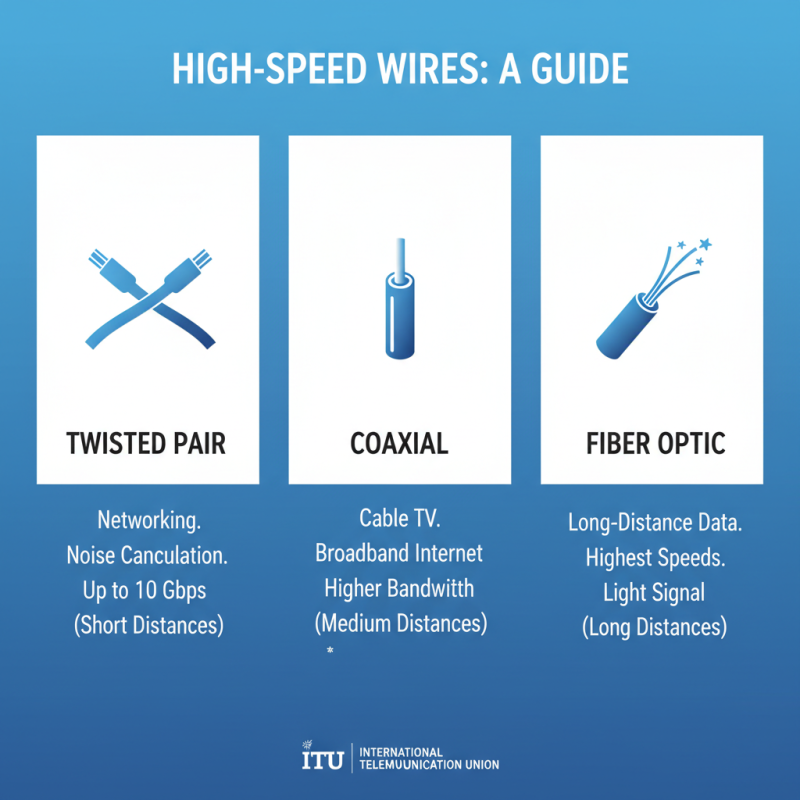

When selecting high-speed wire, understanding the different types is crucial. Commonly, there are twisted pair, coaxial, and fiber optic wires. Each type has specific applications. Twisted pair wires are often used in networking due to their effective noise cancellation. According to a report from the International Telecommunication Union, twisted pair cables can support up to 10 Gigabits per second over short distances.

Coaxial wires offer a different set of benefits. They are commonly used in cable television and broadband internet. Their construction allows for high-frequency signals to be transmitted with minimal loss. However, they can be bulky and less flexible compared to twisted pairs. Some studies suggest that coaxial cables may suffer signal degradation over long distances.

Fiber optic wires stand out when it comes to speed and distance. They transmit data using light, which is faster than electrical signals. According to the Fiber Broadband Association, fiber optic connections can reach speeds up to 100 Gbps. However, their installation can be more complex and costly. As these technologies evolve, reevaluating the specific needs of a project is essential for optimal performance. Balancing cost, speed, and installation complexity may lead to trade-offs that impact project outcomes.

Evaluating Wire Materials: Copper vs. Aluminum in High-Speed Projects

When choosing wire for high-speed projects, material matters greatly. Copper and aluminum are the primary contenders. Copper boasts high conductivity, typically around 60% better than aluminum. This can lead to superior performance in high-frequency applications. However, copper wires are heavier and more expensive. A study showed that copper lost approximately 6% of signal quality over long runs.

Aluminum, on the other hand, is lighter and more cost-effective. It has a conductivity rate of about 61% that of copper. Some industry experts argue that aluminum's price advantage makes it attractive for larger installations. However, corrosion can be a concern. In certain environments, aluminum can degrade faster, leading to increased resistance. This is critical for high-speed applications where signal integrity is paramount.

So, while copper might offer better conductivity, the considerations of weight and cost cannot be ignored. An improper choice in materials could mean lower efficiency. Some projects may benefit more from aluminum, especially where budget constraints exist. Balancing these aspects is crucial when selecting the right wire for specific needs.

How to Choose the Best High Speed Wire for Your Projects?

| Wire Material | Conductivity (%) | Weight (lbs/1000 ft) | Cost per 100 ft ($) | Corrosion Resistance |

|---|---|---|---|---|

| Copper | 100 | 20 | 10 | Moderate |

| Aluminum | 61 | 14 | 6 | Good |

Key Electrical Specifications to Consider for High-Speed Wires

When selecting high-speed wire for your projects, understanding key electrical specifications is essential. One crucial factor is the wire's gauge. For high-frequency applications, thinner wires can minimize signal loss. However, thinner gauges may also lead to higher resistance. According to the National Electrical Code, a balance is vital for optimal performance.

Another important aspect is the wire's insulation type. Different materials like PVC or FEP can handle varying temperatures and improve signal integrity. A report from the Institute of Electrical and Electronics Engineers states that the right insulation can enhance data transmission rates significantly. Inadequate insulation could lead to interference, impacting overall project success.

Additionally, consider the maximum voltage rating. High-speed wires should withstand specific voltage levels without risk of breakdown. To ensure reliability, check the manufacturer's specifications. A miscalculation here could result in project delays or failures. Always evaluate the trade-offs involved in wire choice to enhance project outcomes while avoiding common pitfalls.

High Speed Wire Specifications Comparison

Analyzing Signal Integrity in High-Speed Wire Selection

When analyzing signal integrity in high-speed wire selection, several factors come into play. The wire's geometry is crucial. A well-designed wire can significantly reduce interference. For instance, twisted pairs or coaxial designs help minimize crosstalk. These design choices directly influence the wire's performance in high-frequency applications.

Another aspect to consider is the insulation material. Different materials have various dielectric properties. Choosing the right insulation can enhance the wire's ability to maintain signal integrity. However, many overlook this detail, leading to potential issues. It's not just about speed; it's also about maintaining clarity.

Testing is often neglected in the selection process. Engineers may assume wire performance based on specifications alone. Real-world testing can reveal performance issues that specs don’t cover. Making time for these tests can prevent costly mistakes down the line. Every project is unique. Understanding your specific needs is vital for successful high-speed wire selection.

Related Posts

-

2025 Guide: How to Choose the Best Copper Wire for Your Projects

-

How to Choose the Right Outdoor Extension Cord for Your Seasonal Needs and Safety Compliance

-

Unlocking the Advantages of Wire Feed Welders: Efficiency, Precision, and Cost-Effectiveness in Modern Fabrication

-

What are Electrical Wire Connectors? Exploring Their Types, Uses, and Market Trends in 2023

-

What is the Importance of Using Outdoor Extension Cords for Your Projects

-

7 Benefits of Using Flat Plug Extension Cords for Home and Office Efficiency